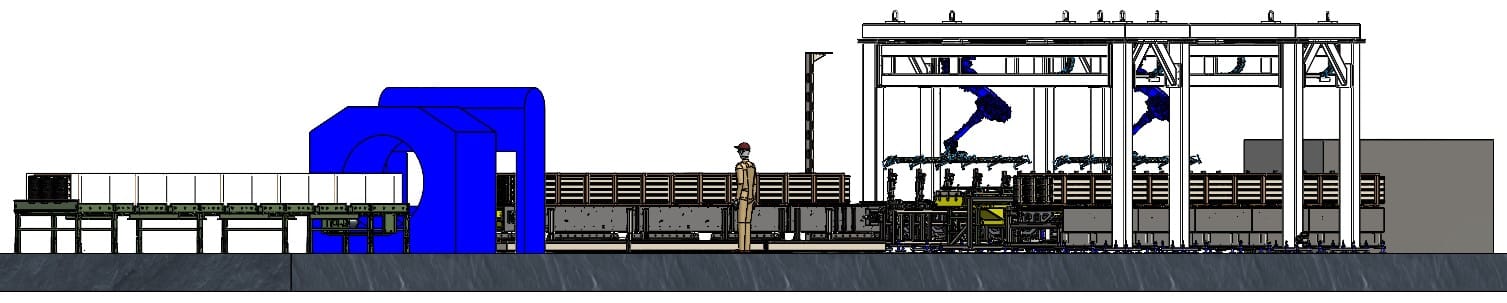

Robotic Panel Handling System

Metal & Composite Panel Handling System

Metal & Composite Panel Handling System

Automated handling of large and bulky metal and composite panels

- Builds bundles per job or for bulk stock

- Handling up to 35′ long parts

- Ability to alternate/flip panels when bundling

- 2 positions for continuous operation

- Automatic wrapping of bundles

Details

- Overall Machine Footprint: 220” X 1460” (18.3’ x 121.6’)

- Product Dimensions: min 4’ to max 35’, 16” width

- Max Bundle Size: 76 panels

- Max Lifting Payload:

One-Robot 40 lb

Two-Robots (larger panels) 80 lb - Hand Stack Panels: over 35’ long in manual mode

- 36” Center to Center spacing of 2” X 4” studs packaging studs

- System has guarding on all moving parts and meets all OSHA and RIA requirements (system guarding is not shown for clarity)

BHS Robotics Solutions

- Builds bundles per job or for bulk stock

- Handling up to 35′ long parts

- Ability to alternate/flip parts when bundling

- Ease of crating with built-in strapping guides and crating positions

- 2 positions for continuous operation

- Automatic wrapping of bundles

- Streamline material handling space

Advantages

- Improves Safety

- Increases Efficiency

- Increases Throughput with Continuous Operation

- Increases Flexibility for Part Style Changes

- Ensures Consistency and Accuracy

Have a similar project? Interested in more information? Let BHS Robotics help.

"*" indicates required fields