PROJECT SUMMARY

BHS Robotics applied our AI + 3D based vision for bulk bin picking and recipe kitting of hand-held snack food packages.

THE CHALLENGE

A maker of specialty snack food products was challenged to keep up with growing demand and a shrinking labor force. The snacks come in a variety of flavors, with each flavor being produced in bulk and then brought to a manual packing line to fill orders, based on customer preference for flavors and quantities of each. An automated solution was needed to provide reliable packing capacity for the customer with flexibility for packing any combination of customer SKU selection.

THE SOLUTION

BHS Robotics designed a robotics handling system, combined with MechMind advanced 3D vision and deep learning software, to pick product from bulk bins and pack based on order requirements.

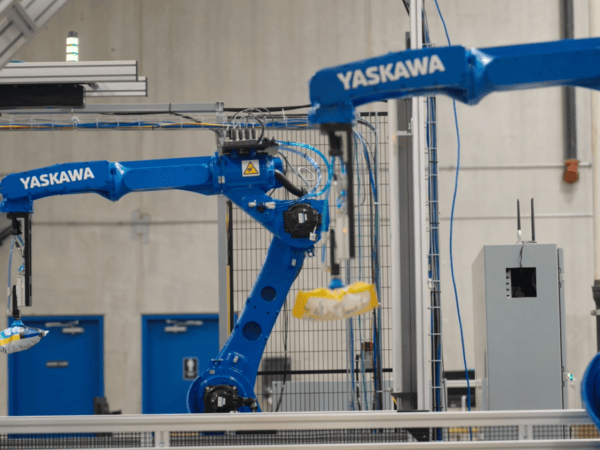

The system incorporates handling conveyors to transfer boxes through the filling stations. Six identical filling stations are provided, each with a six-axis robot and a vision camera.

Bulk bins of product are positioned in the loading stations below the vision camera. Advanced 3D vision determines which product in the bin is accessible to the robot and communicates the coordinates and orientation of product to the robot.

Using a product specific vacuum tool, the robot will pick the item from the bin and transfer it to the conveyor.

Cases are tracked and sequenced on the conveyor as they move through each packing station. Software determines the specific “recipe” of flavors required for the customer order and the robots place the variety and quantity of product into the case.

Cases move down the conveyor to receive product at each filling station until the case is full. The cases then transfer to the downstream processes for weighting, closing and labelling.

At the end of the line, a robotic palletizer removes cases from the conveyor and arranges them on pallets for shipping.

IMPACT TO THE CUSTOMER

Thanks to the BHS solution this customer is able to commit to customer deliveries without worrying about the availability of transient labor. Throughput is predictable and management is able to focus on market growth and product quality, instead of constantly hiring, training and scheduling resources.

Contact us to learn more about how BHS Robotics can add value to your business with flexible packing solutions!