PROJECT SUMMARY

The ProFeeder solution is a standard product from BHS Robotics built to support the challenges of the corrugated packaging industry. Automate the loading of almost any Die Cutter and Specialty Folder Gluer machine with the ProFeeder by BHS Robotics.

THE CHALLENGE

Manual loading of corrugated converting machines is physically challenging work for operators. Loading speeds are compromised when the operators become fatigued, and they become at risk of injury. Large boards require two operators to load which increases costs and affects throughput of the facility.

Floor space is limited, since most existing converting facilities are designed with space allocations for manual loading.

THE SOLUTION

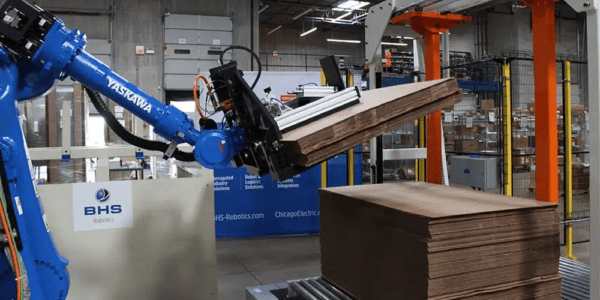

BHS Robotics designed an automatic loading solution to separate operators from strenuous activity and to ensure consistent loading of the system.

The system incorporates a six-axis robot with a servo-controlled gripper assembly. This arrangement provides for the greatest flexibility of equipment positioning and flexibility for product variations. The system is capable of processing sheet sizes from 11”x16” up to 66”x120” without any changeover or reprogramming.

A conveyor system is provided to transfer incoming stacks into the robot cell. Sensors determine the stack position to ensure consistent pickup by the robot. When the stack is in position a backstop is shuttled behind the stack to ensure the stack stays straight and in position when the robot is pulling material from the stack.

The operator can select the product type from the digital display and can also adjust the stack height based on preference for the product or machine being loaded. Sensors at the converting machine ensure a consistent level of material at the machine intake.

The system will continue to load material into the converting machine and will continue to transfer new stacks into the robot cell until the job is complete.

The robot is capable of loading a stack to the machine every 20 seconds, which is equivalent to 12,000 to 20,000 KPM depending on stack height and boarding thickness.

IMPACT TO THE CUSTOMER

Thanks to the ProFeeder, operators have less injury and are more alert throughout the day. Operators can manage multiple machines thereby reducing the company’s reliance on transient labor.

System throughput is faster, more consistent, and predicable.

BHS Robotics specializes in upgrades and automated solutions for the corrugated packaging industry.

Our approach to building customized automation to solve your specific production challenge is what makes BHS Robotics a valued partner.

Contact us to learn more about how BHS Robotics can bring value to your business with automation!