PROJECT SUMMARY

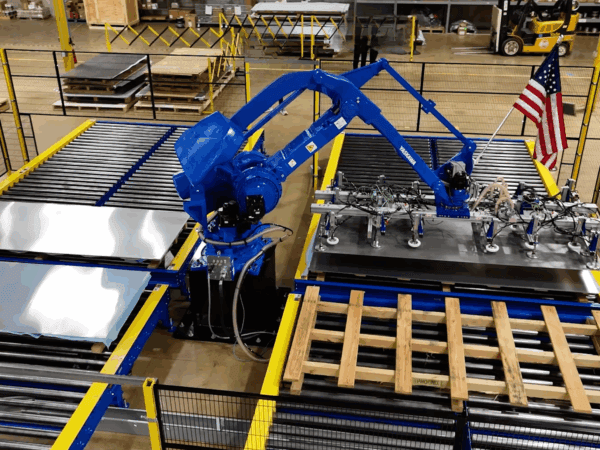

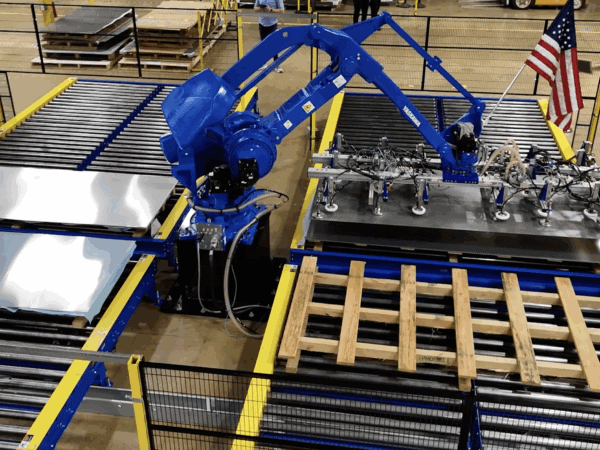

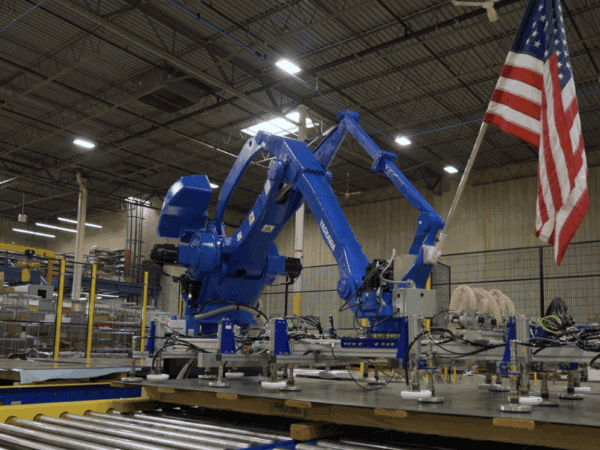

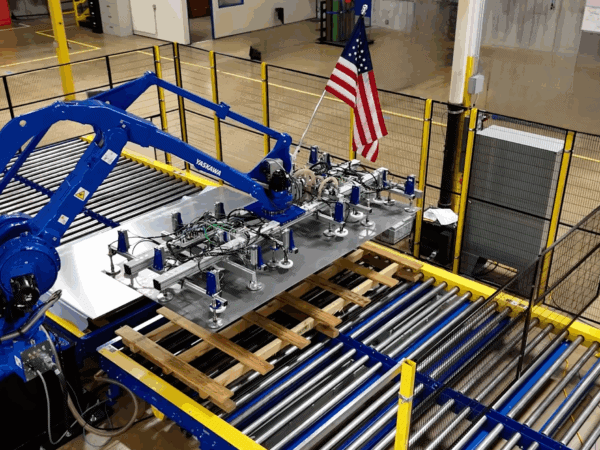

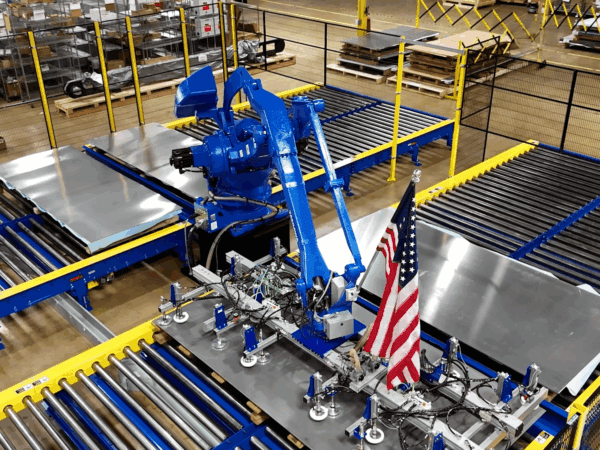

BHS Robotics built a palletizing solution for a sheet metal logistics center. This solution can be applied to handling any type of sheet, including plastics, glass, wood or composites.

THE CHALLENGE

Metal sheets need to be stacked on pallets for shipping to fabricators and manufacturers. Traditionally, this is a manual process requiring multiple people to handle large, heavy sheets.

This manual approach is both inefficient and a safety risk, as finger and hand injuries are common.

THE SOLUTION

BHS Robotics engineered a robotic sheet palletizer that gently lifts and places sheets onto pallets using a highly specialized end-of-arm tooling. The system integrates sensors for alignment verification, ensuring precise placement and consistent stacks.

IMPACT TO THE CUSTOMER

The solution increased throughput in the warehouse, while simultaneously reducing injuries and reducing handling damage to the product.

BHS Robotics can provide robust palletizing solutions for a wide variety of part types, including large, heavy materials. Contact our team to learn how we can bring speed and safety to your sheet handling applications.