PROJECT SUMMARY

BHS Robotics deployed a flexible picking solution which processes over 30 unique and complex part types. Gaskets, o-rings and rubber seals are picked from bulk totes and kitted into mixed bags. This solution reduced costs and improved quality in the customer’s warehouse and logistics center.

THE CHALLENGE

A large global manufacturer of industrial equipment manages complex logistics centers to supply their production facilities and aftermarket network. Manual preparation of small items which are packed into small bags is time-consuming, error-prone, and labor-intensive, especially during peak periods. The facility needed a way to increase order accuracy and throughput without adding headcount.

THE SOLUTION

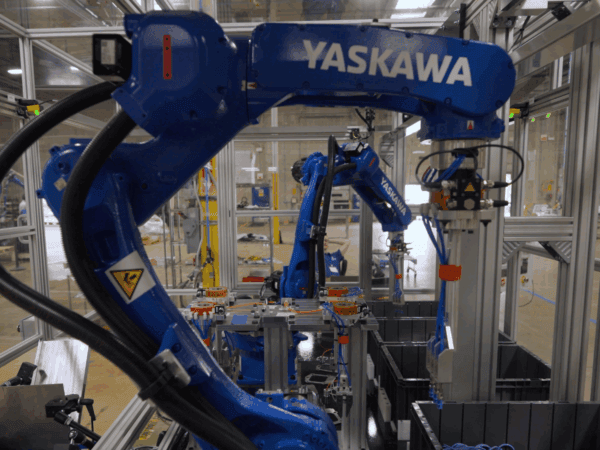

BHS Robotics designed and integrated a flexible picking and kitting cell capable of intelligently managing over 30 SKU’s reliably. The system incorporates automated product identification using advanced vision software. Machine learning models were developed to create reliable identification algorithms for challenging components such as soft o-rings and flexible rubber seals.

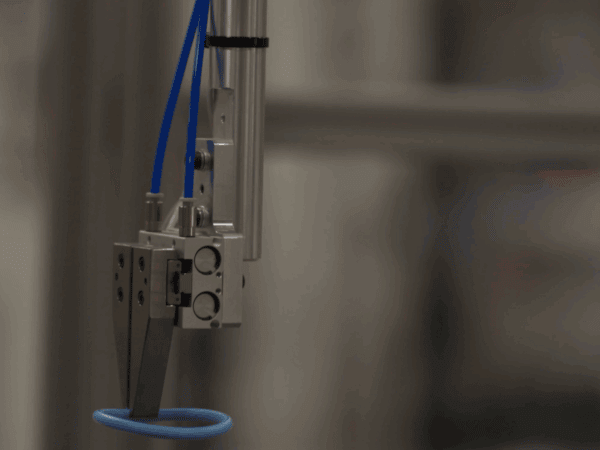

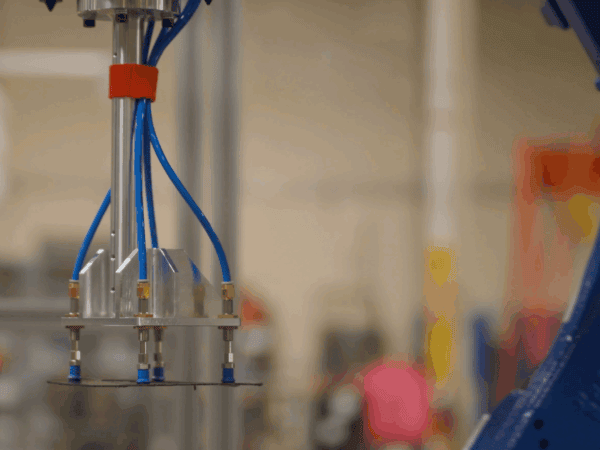

Tooling was also a challenge for this solution, due to the wide variety of part types, shapes and sizes. A carefully engineered array of change-over tooling was developed to work with all part types.

Operators load up to six totes to the system for part supply. The items and qualities to be picked are based on the kit recipe selected from the menu on the operator screen. Two robots work to pick items and pack them into bags which are made available for further warehousing.

The system architecture prioritizes adaptability and compact footprint, allowing it to be deployed quickly and fit seamlessly into existing operations.

IMPACT TO THE CUSTOMER

The customer saw a sharp increase in picking accuracy and order fulfillment speed, with labor resources now focused on higher-value tasks. The process minimized training time and enabled flexibility during demand surges.