PROJECT SUMMARY

BHS Robotics created a unique and flexible solution for staging a wide variety of faster types in a paint masking fixture. Advanced vision technology was employed as a way to locate randomized parts for robot pick and orientation and maintain a high degree of flexibility for dozens of different part types and geometries.

THE CHALLENGE

Fasteners for industrial shelves and racking are often painted to provide a more aesthetic appearance to the finished assembly. This requires masking of the functional threads of the fastener, while exposing the head of the fastener to spray painting operations.

To accomplish this process, a manufacturer was using manual labor to place fasteners in a tray. The tray is uniquely fashioned to position the threads toward the ground, dangling, away from the spray paint. The head of the fastener would be positioned above the plate, exposed to the painting.

Manual operations of this type of very slow and costly. This is a very high throughput operation and was fully constrained by the number of operators and the efficiency with which they work. A faster, more consistent solution was needed.

THE SOLUTION

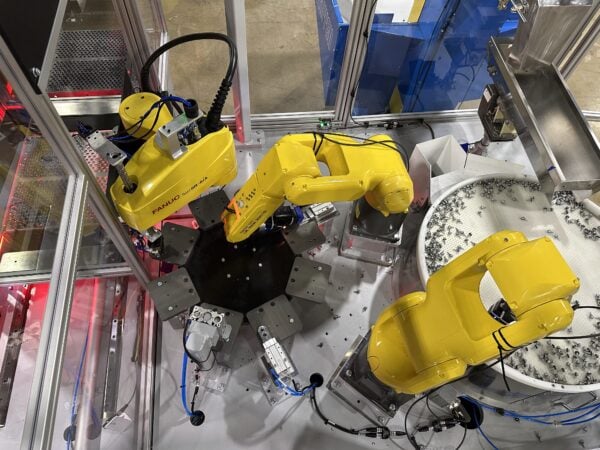

BHS Robotics deployed a high-precision robotic cell featuring vision-guided picking and customized end-of-arm tooling for small-part manipulation.

Fasteners are loading into a hopper for bulk supply to the machine. The hopper dispenses fasteners onto the FlexiBowl table which disperses parts using vibration so they can be observed by the vision system. The vision system identified part types, part position and orientation.

These parameters are communicated to one of two Fanuc LR Mate robots which will pick the fasteners from the FlexiBowl using a custom magnetic picking device.

The robot will orient and transfer the fasteners to a small dial table, where they are inspected, and presented to a Fanuc scara robot for final transfer to the paint trays.

The paint trays are indexed into the system on a small servo table, where another vision system identifies the precise location of each bolt nest. This ensures consistent and reliable placement of product into the tray.

By automating this picking operation, the customer achieved a more consistent throughput, with a clear investment model for scaling the operation. The system is highly flexible for future part changes, without tooling changeover, supporting continuous improvement initiatives on the factory floor.

IMPACT TO THE CUSTOMER

Robotic Flexibility: The system is preconfigured to handle a wide variety of component types based on SKU’s selection from the operator screen.

High Throughput: Achieves 30 picks per minute.

SKU Handling: System is designed to be able to process an unlimited number of SKUs.

Enhanced Efficiency: Consistent throughput for 3 shifts per day. Can run unattended during off shifts.

Automatic Tool Changing: Enables seamless transitions between different component types.

BHS Robotics specializes in the application of advanced vision technologies and robotics to provide flexible processing solutions for high mix environments our clients.

Contact us to learn more about how BHS Robotics can add value to your business with flexible automation!