PROJECT SUMMARY

BHS Robotics developed a flexible material handling solution for large, heavy, metal components. A very high degree of flexibility is incorporated with the use of vision technology, and a generic magnetic pick-up tool.

THE CHALLENGE

Not all warehousing environments utilize structured boxes and pallets. In the heavy machinery industry, large flame cut steel parts, and large steel weldments are stored in bins, often in outdoor yards.

When these parts are needed for production or aftermarket supply, the relevant bins are retrieved and brought to logistics areas where people are required to identify the needed part(s) and move them from the storage bins to a shipping box or pallet. Often these parts are very heavy, requiring multiple people to lift, or the use of hoists and cranes to do the work. This is very time consuming and puts manpower at risk of injury.

A solution was needed to automatically identify parts in bins and move them from the storage bin to the shipping bin. A high degree of flexibility was needed for hundreds of different weights, geometries and SKU’s.

THE SOLUTION

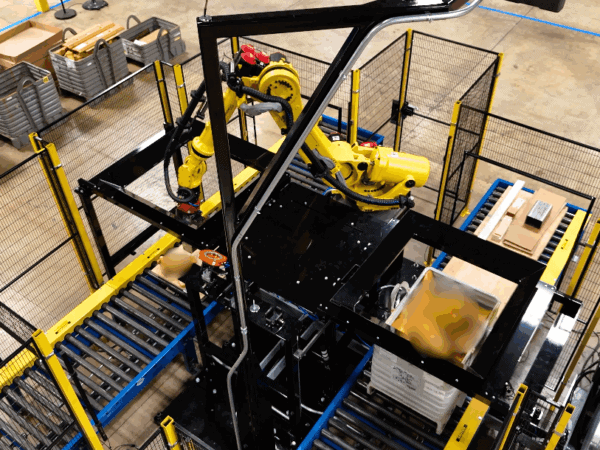

BHS Robotics created a flexible pack out system powered by a Fanuc R-2000iC210F robot and Sick vision system that autonomously identifies incoming parts and determines the optimal pick and pack location in real time. There’s no need for pre-training the system on each SKU.

The vision system can scan a bin of parts and identify pickable surfaces. The robot is tooled with a Magswitch AR 100 magnetic gripper. With this arrangement the robot can automatically pick parts with an available surface, up to 150lbs.

IMPACT TO THE CUSTOMER

With hundreds of SKUs managed seamlessly, the customer significantly improved operational throughput while eliminating dull and dangerous work from their personnel.

BHS Robotics delivers cutting-edge solutions for high-mix, low-volume operations—contact us to learn how we can apply robust and flexible automation to your dull and dangerous processes.