PROJECT SUMMARY

BHS Robotics implemented a fully automated dunnage handling system for a major corrugated board producer, reducing manual labor and streamlining packaging workflows.

THE CHALLENGE

One of the biggest challenges in high volume corrugated plants is maintaining enough personnel to put edge protectors on the finished stacks of board. This is traditionally a manual process which needs to be done before strapping and shipping the product.

Facilities may employ 5-10 people per shift for this process. If the shift is short-handed at any time, the throughput will suffer which forces the producer to lower the speeds of upstream equipment, costing them money in lost revenues.

THE SOLUTION

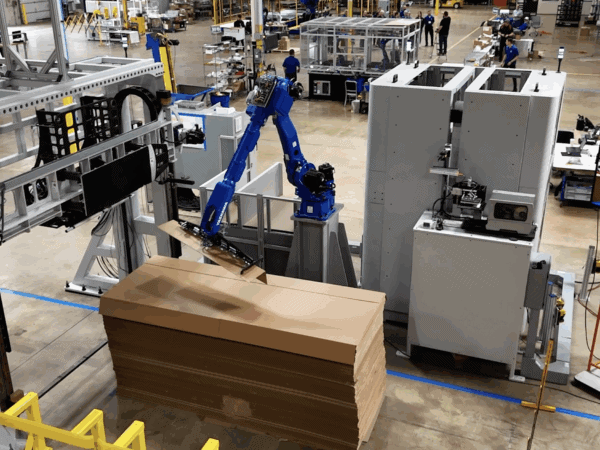

BHS Robotics developed a robotic system capable of locating the product position on the conveyor, placing top-sheets, edge protectors and tie-sheets to the product stack.

The “Dunnage Bot,” integrates with existing conveyor systems and uses high resolution machine vision cameras to identify when the product is in position.

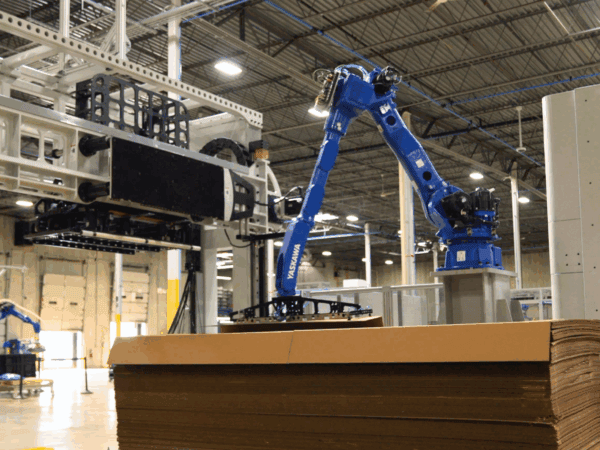

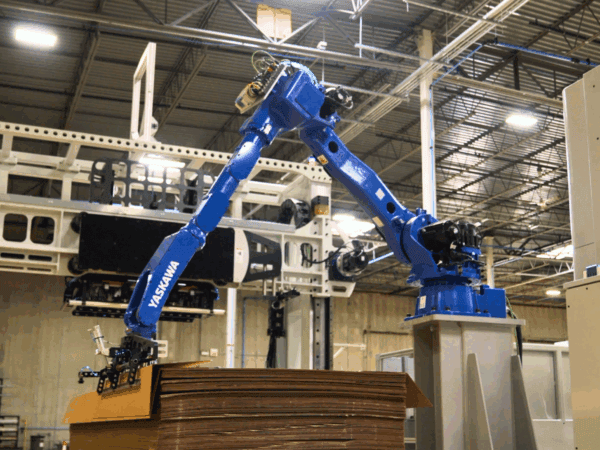

Dunnage materials are pre-staged in racks for the robot to select and position on the product. The Yaskawa robot is tooled with a vacuum gripper, capable of retrieving corrugated sheets from four different size stacks. The robot pulls the right material based on box size and product type.

The vacuum tool incorporates features to fold the sheet 90 degrees, to form an edge protector, or without folding for a topper sheet.

An independent mechanism spans the conveyor to insert tie-sheets into split stacks. These tie-sheets are important to stabilize the split stacks so they do not shift or topple during transport. The conveyor moves the product stack forward to a contact surface. The system will engage the stack at a predefined (programmable) height. The stack is automatically lifted to create a small gap in the product stack. A tie-sheet is automatically dispensed and inserted into the gap. The entire mechanism will then retract and elevate to allow the product stack to pass on the conveyor line.

The system also incorporates automatic label printing, label applying and label verification for the product stack.

IMPACT TO THE CUSTOMER

The customer eliminated repetitive manual tasks, freeing staff to manage more dynamic operations. This concept can relieve the production of the human “bottle neck” to allow for more consistent throughput and capacity forecasting.

BHS Robotics offers custom dunnage handling systems for packaging operations for corrugated and other industries. Contact BHS Robotics to automate your end-of-line packaging and logistic processes.